Coir Mat Manufacturing Process

Planet coco s production process starts with the procurement of freshwater grown coconut husks.

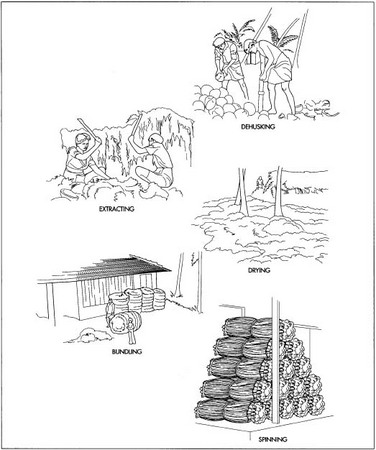

Coir mat manufacturing process. Rubberized coir manufacturing 5 total 1995 the income level for the labours in the cluster is rs 350 for male workers and rs 250 for female workers. The curing process for the coconut husk take over 6 weeks after this process the coconut fibers are separated and graded. Gemunu amarasinghe 48 940 views. Coir is the fibrous material found between the hard internal shell and the outer coat of a coconut.

Secondly whether coir mats or matting or floor covering with vinyl pvc backing. Other business videos to watch. Coir fibre units suffocate due to the price rise in raw material husks and stagnancy in coir fibre price. The manufacturing process harvesting and husking 1 coconuts that have ripened and fallen from the tree may simply be picked up off the outer layers covering the coconut seed are processed and spun into fibers commonly.

Rubber floor mats include industrial rubber mat anti static mat anti vibration mat anti fatigue mat high school wrestling mats rubber mats for use at home entrance mats interior mats and so on. Key concern areas of the cluster apparent stagnancy in coir fibre market perceived. Coir ˈ k ɔɪər or coconut fibre is a natural fibre extracted from the outer husk of coconut and used in products such as floor mats doormats brushes and mattresses. In europe and asia brown coir mats may be sprayed with latex rubber for use as padding in mattresses or automobile upholstery.

Lesson for finising process of coir mats duration. So while you may be aware of the many benefits that they can bring to your home or business gaining a little background insight can be very useful too. Door mats might not stand out as being the most obvious product to boast an interesting manufacturing history but the truth of the matter is that coir matting is produced in a fascinating fashion. The company from a coir yarn trading company to a fully fledged manufacturer of all contemporary floor covering products the current range includes mats rugs and carpets made from coir jute sisal rubber cotton.

In the year 1993 the company has changed its name to ram coir mills and now is proud to have exported to all parts of the world. However the major use of rubber floor mats is to effectively remove and trap dirt and. Coir door mats manufacturing sri lanka duration. Firstly whether the process of manufacturing embedding coir yarn into vinyl pvc compound and curing by heating or cooling which is called tufting or a process other than those processes mentioned in headings 5701 to 5704 of the customs tariff and the hsn explanatory notes to chapter 57.