Coating Fibers With Boron Nitride Ceramic

When deposited at low temperatures bn can be amorphous or turbostratic.

Coating fibers with boron nitride ceramic. The bn coating creates a non wetting surface that gives the graphite parts non stick properties when in contact with molten aluminum magnesium zinc and its alloys. This product does not contain boron nitride. The mass content of boron oxide is between 2 and 5. Adheres well to all refractory surfaces dense or porous and can be used as glue to join ceramic materials.

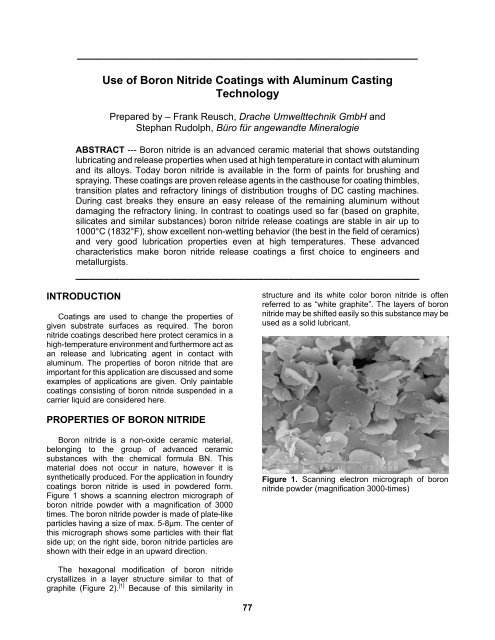

The boron nitride coatings can be used with refractory materials made by adtech such as alumina porcelain rod ceramic fiber tubes ladle shroud flow channels etc. Applicable for all environments from 300 c 572 f to 1500 c 2732 f. The particle size of boron nitride is between 20 microns and 50 microns and the mass content of boron nitride is 30 85. Boron nitride was deposited by low pressure cvd onto the as received and variously heat treated woven carbon fiber at 1 torr and 800 c in a fused silica tube.

Abstract a process involving dip coating of ceramic fibers in h 3 bo 3 solution followed by reaction with nh 3 has resulted in the formation of a bn coating on nicalon and a carbon coated nicalon fiber. Bn coated c nicalon fiber maintained its strength during the coating process while the bn coated nicalon did not. It has dry lubricating properties. The deposition time was 60 min.

The most important advantages. Boron nitride bn has been deposited in situ on carbon fibers of 3d fibrous preforms by isopressure isothermal chemical vapor infiltration icvi from bcl 3 nh 3 h 2 mixtures the aim being to produce a coating of uniform thickness in the whole preforms. About boron nitride coating precision ceramics boron nitride coating creates a layer of boron nitride powder on a variety of materials from metals and graphite to ceramics and organics this coating is incredibly versatile. The excellent thermal stability high impermeability to gas and liquid and electrical insulation make atomically thin boron nitride potential coating materials for preventing surface oxidation and corrosion of metals and other two dimensional 2d materials such as black phosphorus.

Reduced maintenance costs and downtime. Our boron nitride coating is also suitable for ceramic materials and metals. It should be noted however that not all bn coatings are the same. The deposition temperature has been lowered to 773 k.

Aside from carbon boron nitride bn is the only fiber coating that has enabled graceful failure in non oxide ceramic composites. The n 2 g nh 3 g and bcl 3 g gas flow rates were 400 500 and 125 standard cubic centimeters per minute sccm respectively.