Ceramic Wool Rigidizer

Our rigidizer is the most commonly used colloidal silica for bonding refractory fibers and rigidizing refractory fiber shapes and boards.

Ceramic wool rigidizer. Curing is a function of the size of the shape and its geometry. Purchase 5 gallons and save. 5 0 out of 5 stars 6. Simwool rigidizer coating for ceramic fiber blanket 1 quart.

Surface coating for ceramic fibre materials exposed to high velocity gases. Simwool rigidizer coating for ceramic fiber blanket 1 gallon. Simwool rigidizer silica sol is a refractory coating for ceramic fiber used for increasing the surface hardness of any flexible thermal insulation or refractory product like ceramic fiber blanket. It can be easily applied by spraying rolling dipping or brushing.

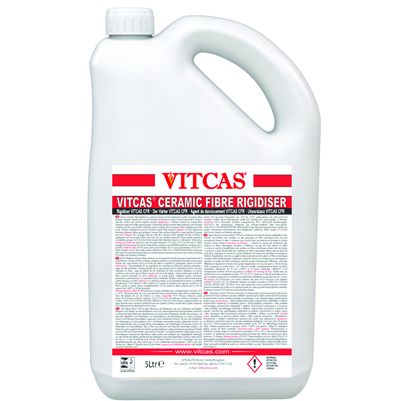

Simply dip the brush into the rigidizer then paint the liquid onto the wool. Vitcas ceramic fibre rigidizer is a silicate compound for treating the surface of ceramic fibre blanket modules boards and vacuum formed components to give a hard outer shell in order to seal the surface and protect against erosion. 5 0 out of 5 stars 8. Coat all exposed ceramic fiber.

They are generally used to increase the durability and surface erosion resistance of fiberfrax blanket and board products. Simwool rigidizer coating for ceramic fiber blanket 1 gallon. Ceramic rigidizer or so called kaowool rigidizer. 4 8 out of 5 stars 15.

Refractory ceramics rigidizer can be applied to ceramic fiber blanet or kaowool blanket. Kaowool rigidizer for ceramic fiber receives its bonding action from the removal of physical water. Simwool rigidizer coating for ceramic fiber blanket 1 gallon. Crs rgd is an economical 40 concentration silica sol of 14 nanometer diameter amorphous silica spheres.

Only 10 left in stock order soon. 5 0 out of 5 stars 6. The rigidizer is tinted blue so that you can see where it has been applied. An application rate of one gallon per 25 square feet 7 6 m2 of ceramic fiber surface will render a hard surface without.

Rigidizer w hardener contains an organic wetting agent to promote saturation into the substrate whereas rigidizer hardener tends to remain on the material. Once coated let it dry for 24 hrs if ambient temps are low you can place a fan on low to circulate air through the forge chamber which will help dry the rigidizer. Rigidizer and rigidizer w inorganic liquid hardeners have a temperature grade rating of 1260 c 2300 f.