Ceramic Vs Zirconia Flap Disc

They are the newest grain innovation and represent the ultimate in performance providing an aggressive consistent cut under moderate to high pressure.

Ceramic vs zirconia flap disc. This article is about zirconia vs ceramic flap disc the main aspects are service life use efficiency use temperature and their respective applications. Flap discs are almost always used on right angle grinders and they are applied to your work at an angle or parallel to it. Blueshark manufacturer different abrasives oxide flap discs and this brief compare testing just want to find what is the grinding speed difference between ce. The flaps can be applied to the work at an angle or flat.

Aluminum oxide for general use and maintenance repair operations. While both are great for aggressive work and excel at a 24 120 grit their differences become more apparent in their longevity structure and abilities. Coated abrasive flap discs 60 or 80 grit ceramic alumina. Flap discs hook loop discs quick change discs.

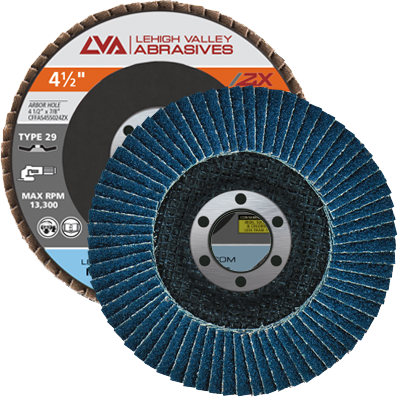

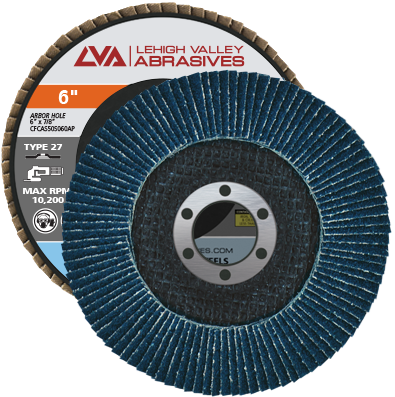

Picking the right flap disc shape conical shape type 29 or a flat shape type 27 provides different performance features. You can find a variety of sanding belts discs and more in both zirconia and ceramic. Ceramic is available in grits 24 120. Grinding wheels so why would you choose a flap disc over a grinding wheel.

Flap disc shape because flap discs are used almost exclusively on right angle grinders they are designed with a hub that allows work to be done on the face flaps. The cibo range of ceramic flap discs are ideal for. They can be used for edge. Used primarily on metal applications.

Conical flap discs are your best friends when you need to remove a lot of material in a small amount of time. The flaps can be applied to the work at an angle or flat. Ceramic flap discs have been proven to last anywhere between 3 and 5 times as long as zirconia flap discs. Zirconia alumina for stainless steel.

Grinding mill scale on steel and. Ceramic is usually red or orange in color. The shape of the flap disc whether conical type 29 or flat type 27 provides different performance features as illustrated in figure 1. Flap discs are available in two shapes.

And materials you are using. Zirconia alumina blend for exotic and heat sensitive metals. Zirconia vs ceramic flap disc. What is zirconia flap disc.

Light deburring and finishing. Like ceramic zirconia alumina has a self sharpening characteristic which gives it a long product life and is great for aggressive heavy grinding of metals such as carbon steel and stainless steel.